The Cement Ball Mill: A Comprehensive Guide to Function, Selection, and Advantage

In the world of cement production, grinding is a fundamental and energy-intensive process. The cement ball mill stands as a critical piece of equipment in this phase. This robust machine transforms clinker and other raw materials into the fine powder we know as cement. Many industries rely on this technology for consistent and efficient grinding. Understanding the ball mill principle and its application is key to optimizing a plant’s output. This guide provides a deep dive into the working principle of cement ball mill, its components, and how to select the right one for your needs.

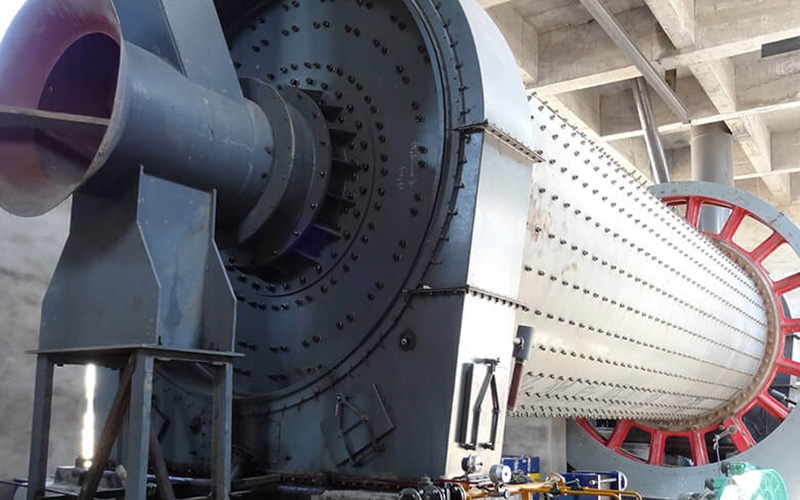

Core Function and Working Principle of Cement Ball Mill

The primary function of a cement ball mill is simple: to grind the clinker, gypsum, and other additives into a homogeneous cement powder. This powder must possess a specific surface area and particle size distribution to achieve the desired strength and setting properties.

The working principle of cement ball mill is straightforward and highly effective. It operates on the concept of impact and attrition.

A cement ball mill is a horizontal, rotating cylinder. The cylinder is partially filled with grinding media, usually steel balls. As the mill rotates, these balls are lifted to a certain height. They then cascade and drop onto the material to be ground. This action crushes the clinker through impact. The rotation also causes the balls to rub against each other and the liner, creating attrition that further grinds the particles. The entire system is a closed circuit. A separator classifies the ground material, returning oversized particles for further grinding and allowing the fine product to proceed.

Key Components and Driving Mechanisms

A cement ball mill is a complex assembly of several key parts. Each component plays a vital role in its operation.

- Mill Shell: This is the robust, cylindrical outer structure that provides support and contains the grinding process.

- Grinding Media: These are the hardened steel balls that perform the actual grinding. Their size, composition, and gradation are critical for efficiency.

- Liners: These protect the inner shell of the mill from wear and tear. They also help to lift the grinding media for optimal impact.

- Diaphragms: These partition the mill into multiple chambers, allowing for a more efficient grinding process from coarse to fine.

- Drive System: This is the powerhouse of the mill. It typically consists of a high-power motor, a gearbox, and a pinion that meshes with a girth gear on the mill shell to induce rotation.

When considering a ball mill for sale, it is crucial to evaluate the quality and design of these components. Reputable cement ball mill manufacturers design their systems for maximum durability and minimal maintenance.

Primary Applications: Ball Mill for Cement Grinding

The most common application for this technology is, of course, in cement ball mill systems. Specifically, a ball mill for cement grinding is used in two key stages:

Finish Grinding: This is the final step where clinker is ground with a small amount of gypsum to produce the final cement product. The precise control offered by a ball mill is essential for meeting quality standards.

Raw Material Grinding: In some plant configurations, ball mills are also used to grind the raw mix (limestone, clay, etc.) before it is fed into the kiln.

How to Select the Right Cement Ball Mill

While Vertical roller mill technology has gained popularity for its energy efficiency, the cement ball mill remains a preferred choice due to its reliability, ability to handle moist materials, and producing cement with excellent long-term strength development.

Choosing the correct cement ball mill is a critical decision. The wrong choice can lead to high energy costs, low production rates, and poor product quality. Here are the key factors to consider:

- Production Capacity: Determine the required tons per hour of finished cement.

- Feed Size: The initial size of the clinker and other materials entering the mill.

- Required Fineness: The target Blaine value or particle size distribution of the final cement.

- Grinding Media: The type, size, and charging ratio of the grinding balls.

To simplify the selection process, use the following table as a guide:

| Selection Criteria | Key Questions to Ask | Impact on Operation |

|---|---|---|

| Capacity & Size | What is my target hourly output? What are the physical space constraints? | Determines the mill dimensions and motor power. |

| Drive System | What is the available power source? Is a variable speed drive needed? | Affects energy consumption and operational flexibility. |

| Mill Configuration | Is a two-chamber mill necessary for my process? | Influences grinding efficiency and product fineness. |

| Material Hardness | How abrasive is my clinker and raw mix? | Determines the required hardness of liners and grinding media. |

Leading cement ball mill manufacturers can provide detailed technical specifications and simulations to help you make the best choice for your specific application.

The Distinct Advantages of Using a Cement Ball Mill

Why does the cement ball mill remain a dominant force in the industry? Its advantages are numerous and significant.

- High Reliability: The design is simple and robust, leading to high operational availability and long service life.

- Product Quality: It produces cement with a well-rounded particle shape and excellent particle size distribution, which is linked to superior concrete strength.

- Operational Flexibility: Ball mills can handle a wide range of materials and moisture contents. They can also be easily adjusted to produce different cement types.

- Maintenance Ease: The design allows for straightforward inspection and replacement of worn parts like liners and diaphragms.

- Proven Technology: The ball mill principle is a time-tested method, and plant operators are generally very familiar with its operation and maintenance.

While a Vertical roller mill may offer lower specific energy consumption, the cement ball mill often provides a lower overall cost of ownership when factoring in maintenance and product quality.

Cement Ball Mill Frequently Asked Questions (FAQ)

Q1: What is the basic definition of a cement ball mill?

A cement ball mill is a large rotating machine used to grind cement clinker, along with other additives like gypsum, into a fine powder. This powder is the final product, known as Portland cement.

Q2: How does a ball mill differ from a simple mixer?

A mixer only blends components. A ball mill uses impact and attrition to physically break down and reduce the size of solid particles. The grinding action inside a ball mill fundamentally changes the physical properties of the material, creating a much finer and more reactive powder.

Q3: Is a ball mill used only in the cement industry?

No. While ball mill for cement grinding is a primary application, the technology is versatile. Ball mills are widely used in mining to grind ores, in the chemical industry, and in paint and pigment production.

Q4: What are the main advantages of a cement ball mill over other grinding technologies?

The key advantages include exceptional reliability, high-quality product output with excellent strength characteristics, great flexibility in processing different materials, and ease of maintenance. It remains the benchmark for consistent and dependable cement production.