Diverter Valve Selection Guide: Key Considerations and Best Practices

In industrial piping systems, controlling material flow is essential. Diverter valves play a key role here. They reliably guide powders, granules, and other materials from one line to another. This guide explains how these valves work and how to select the right one.

What is A Diverter Valve?

A diverter valve is a flow control device. Its main function is to change the path of a material. It typically has one inlet and two or more outlets. The valve directs the full material stream to a chosen outlet. It does not mix or regulate flow, it simply switches the path. This makes diverter valves crucial for routing materials to different silos, process lines, or packaging units without cross-contamination.

How the Valve Operates

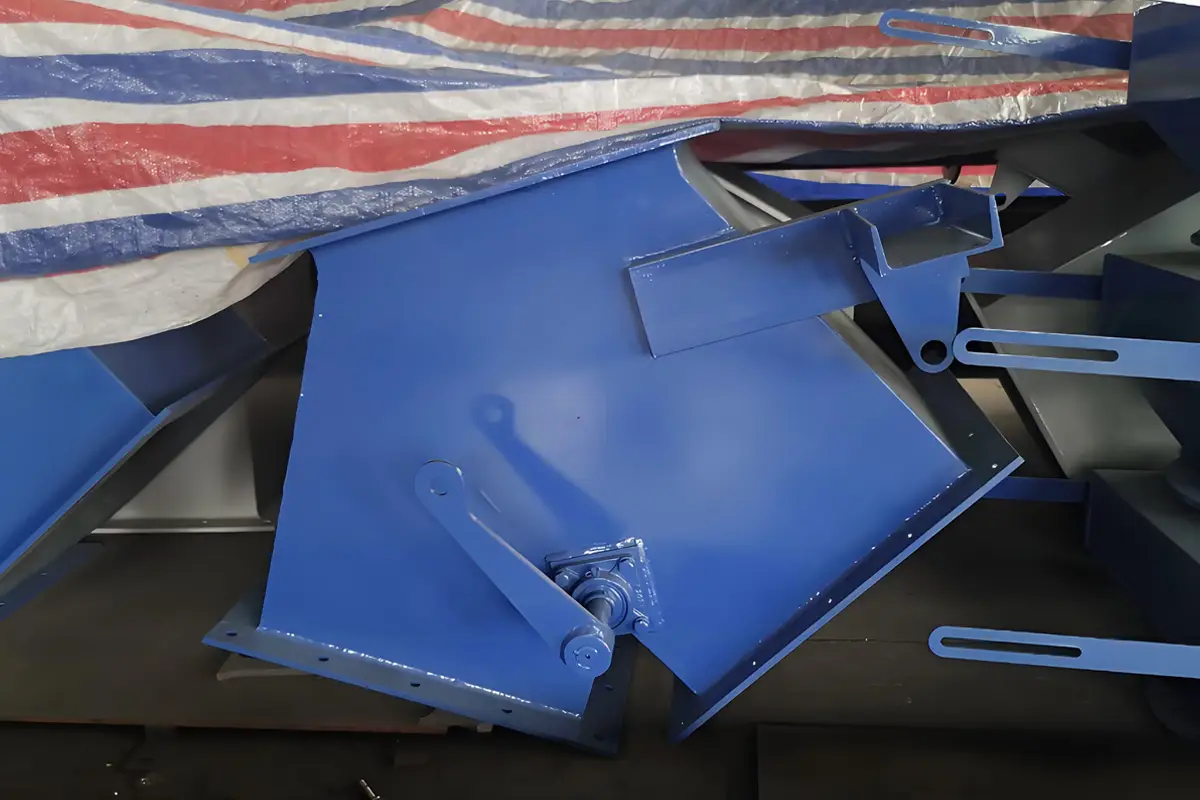

The operating principle is straightforward. An internal diverting element moves to block or open specific flow paths. This element can be a pivoting flap, a sliding plate, or a rotating rotor. An external actuator drives this movement. For example, in a common two-way design, the element shifts to seal one outlet and open the other. This provides positive and reliable flow direction.

Common Diverter Valve Types

Different applications require different valve designs. Here are the main categories.

By Flow Path

- Two-Way Diverter Valve: This is the standard type. It has one inlet and two outlets. It provides a simple “A or B” switching function.

- 3-Way Diverter Valve: This version offers more flexibility. It can have one inlet and two outlets, or sometimes two inlets and one outlet. This allows for more complex system layouts.

By Special Function

- Equal Divert Valve: This valve features symmetrical flow paths. This design minimizes flow resistance and pressure drop in either direction. It helps maintain product quality and system efficiency.

- Side Divert Valve: This type is built for specific tasks. It diverts material from a main conveyor line to a side destination. It is common in packaging and sortation systems.

Choosing an Actuation Method

The actuator is the muscle that moves the valve. You have three main choices.

- Pneumatic actuators use compressed air. They are fast, powerful, and well-suited for tough industrial environments.

- Electric actuators use an electric motor. They provide precise control and are ideal for clean rooms or where air supply is limited.

- Manual actuators use a hand lever or wheel. They are a cost-effective solution for applications that do not require automation.

Key Industrial Applications

Diverter valves are versatile components. You will find them in many sectors.

- In food and pharma, they route ingredients like flour and powders between mixers and packaging machines. Sanitary design is a priority here.

- The plastics industry uses them to direct different colored pellets to the correct processing machines.

- In chemical plants, they safely transfer various powders to designated reactors or storage vessels.

System Integration and Key Selection Considerations

Selecting the appropriate valve is crucial for stable system operation. The following decision matrix can serve as a reference:

| Consideration Dimension | Key Assessment Points & Options |

|---|---|

| Media Characteristics | Abrasiveness, viscosity, density, temperature, and hygiene grade requirements of the material. |

| Functional Requirements | Required number of outlets, switching frequency, sealing class (e.g., requirement for zero leakage). |

| Operating Environment | Ambient temperature, explosion-proof requirements, presence of vibration, need for sterile or wash-down design. |

| Actuation Method | Availability of stable air source on site, requirements for switching speed, integration method with control system. |

| Valve Body Material | Selection based on media and environment, e.g., Carbon Steel, Stainless Steel (304/316L), or special alloys. |

Core Value Provided by Diverter Valves

Correctly deploying diverter valves in a system can bring significant operational advantages:

- Enhances Production Line Flexibility: One conveying system can serve multiple downstream equipment, improving asset utilization.

- Guarantees Product Purity: Tight seals effectively isolate different materials, serving as a key link in quality control.

- Optimizes Spatial Layout: Replaces complex piping and tee fittings with a single valve, making the system more compact.

- Reduces Operating Costs: Reliable mechanical structure and long-life design minimize maintenance needs and downtime.

Frequently Asked Questions

Q: Does the diverter valve interrupt material flow during switching?

A: The design of most standard diverter valves is “break-before-make,” meaning material flow is briefly interrupted the moment the path switches. However, for specific applications, specially designed “non-interruptive” switching valves exist that can maintain continuous flow during switching, though their structure is more complex.

Q: How to handle sticky materials prone to clogging or bridging?

A: For such materials, it is recommended to select a valve body design with a streamlined flow path and no dead zones, with polished internal surfaces. Additionally, consider adding flow aid devices like bin vibrators or air knockers.

Q: How to evaluate the pros and cons of pneumatic vs. electric actuators?

A: Pneumatic actuators are generally more economical, faster, and inherently explosion-proof but require an air compressor station. Electric actuators offer more precise control, wiring is often easier than running air lines, but they have a higher initial investment and require specific models for explosive atmospheres. The decision should be based on site conditions and control requirements.

Q: What routine maintenance do diverter valves require?

A: Routine maintenance includes: periodically checking the stability of the air supply (pneumatic) or power supply (electric) for the actuator; cleaning the interior based on material characteristics to prevent buildup; and regularly verifying the wear condition of seals and replacing them according to schedule.

When sourcing, remember that a quality aramid filter bag factory in China can be a global partner, providing the technical expertise and manufacturing excellence required for peak bag filter performance.