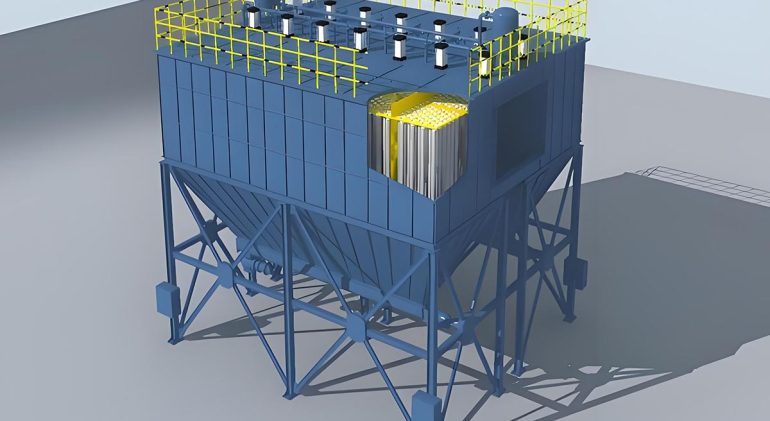

Maintenance Operating Procedures for Pulse Single-unit Dust Collector

Maintenance Operating Procedures for Pulse Single-unit Dust Collector The pulse single-unit dust collector is an efficient air purification device widely used for dust control and environmental protection in industrial production. To ensure its long-term stable operation, improve dust removal efficiency, and extend equipment life, it is essential to develop and strictly implement maintenance operating procedures. I. Daily Maintenance Daily maintenance is essential for maintaining the efficient operation of the pulse single-unit dust collector. It mainly includes the following aspects: 1. Equipment Operation Log Record key parameters daily, including operating hours, pressure differential changes, and cleaning cycles. This helps in the timely detection and handling of abnormalities. 2. Visual Inspection Regularly […]