HMC Series Pulse-Jet Dust Collector: Operation and Maintenance

The HMC series pulse-jet dust collector is a small baghouse dust collector. It was designed after improving upon similar domestic and international products. This dust collector uses a pulse-jet cleaning method. It offers effective dust cleaning, high purification efficiency, and large air volume capacity. It also features long filter bag life, minimal maintenance, and safe, reliable operation. It is widely used for dust removal and material recovery in various industrial settings. These include metallurgy, building materials, machinery, chemicals, mining, and grain processing. It handles non-fibrous industrial dust.

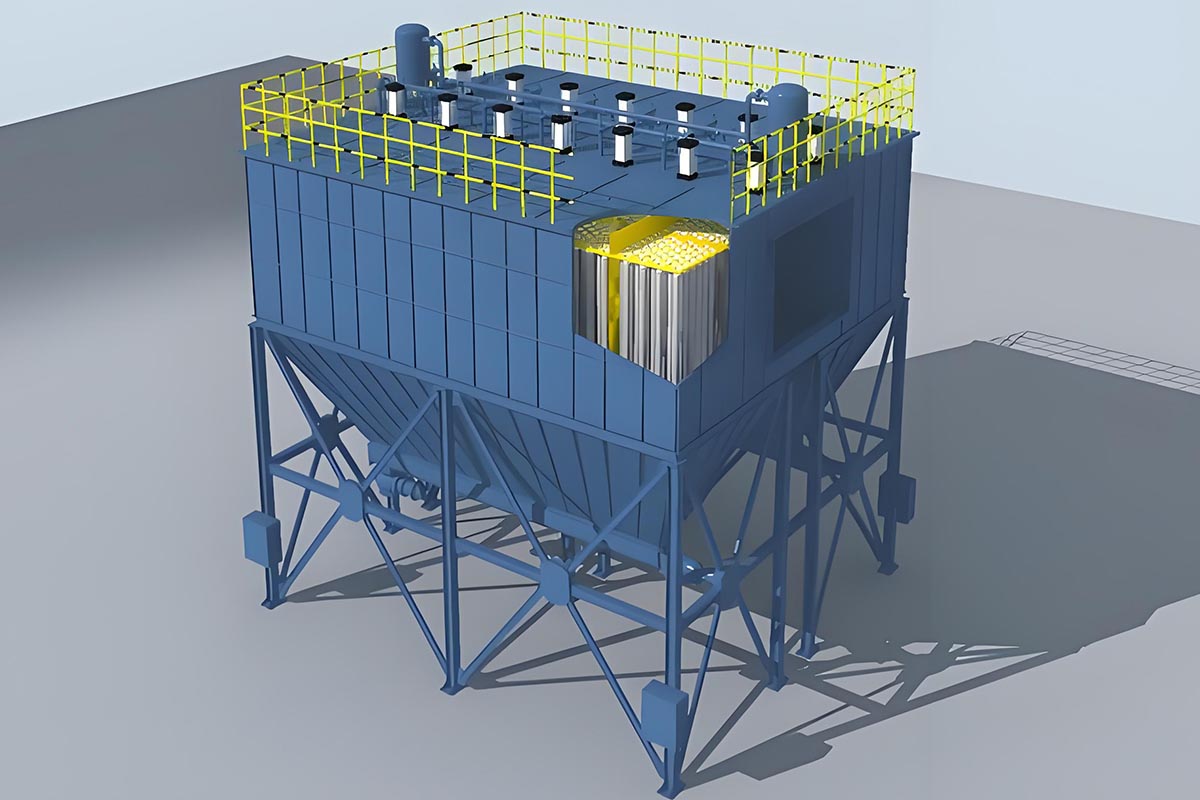

This series includes six standard models. Each model comes in two types. Type A is the standard design with a hopper. Type B has an open flange and no hopper. The main structure consists of several parts. These include the filter chamber, filter bags, bag cages, clean air chamber, dust hopper, dust discharge valve, pulse-jet cleaning device, and electrical control box. The casing uses a fully welded structure. The access door is sealed with foam rubber strips.

Working Principle

Dust-laden gas enters the filter chamber through the hopper or the lower open flange. Heavier particles fall directly into the hopper or dust bin. The gas passes through the filter bags. Dust collects on the outer surface of the bags. Clean air moves into the clean air chamber and is discharged into the atmosphere by the fan.

Dust continuously builds up on the filter bags. Consequently, the system’s resistance increases. When the resistance reaches a set value, the timer relay or differential pressure controller sends a signal. Then, the programmable controller activates. It opens the pulse valves one by one. Compressed air blows through nozzles into the filter bags. As a result, the bags expand suddenly. The reverse airflow dislodges dust from the bags. The dust falls into the hopper or dust bin. Finally, the dust discharge valve removes the dust.

The pulse-jet cleaning cleans one row of bags at a time. Meanwhile, the other rows continue filtering normally. The fan does not stop.

Maintenance and Care

Casing: Tighten any loose screws promptly. Replace any worn-out sealing parts immediately. Repaint areas where paint has peeled off. Also, perform regular repainting. This prevents the casing from rusting.

System Resistance: Monitor the manometer’s pressure differential. If it exceeds the limit, find the cause promptly. Check for these issues. Excessive dust on the bags, blocked pressure gauge tubing or fittings, clogged blowpipes, or malfunctioning pulse valves or controllers.

Filter Bags: Open an inspection port on the clean air outlet pipe. Insert a clean glass tube. After some time, remove and check it. Replace the bag if you find significant dust buildup. We recommend replacing all bags at once. Normally, if one bag is broken, the remaining bags are also near the end of their service life.

Pulse Valves: A properly working valve makes a crisp “poof” sound. If there is a problem, check the following:

- No sound (No blowing): The exhaust port might be blocked. The controller may not be working. The diaphragm might be faulty.

- Weak “poof” sound: The pulse valve spring could be too stiff. The diaphragm might have a small hole.

- Long “poof” sound (Blowing too long): The spring may have lost its elasticity. The throttle orifice might be blocked.

- Continuous sound (Constant blowing): The throttle orifice could be completely blocked. The diaphragm spring might be broken.

- Long, sharp screech: This is caused by air leakage from a broken diaphragm.

Address each cause accordingly. When replacing parts, be careful not to introduce oil or dirt.

Create a maintenance duty schedule. The duty personnel must record operational status. Regularly check if the electronic cleaning control works correctly. Adjust the cleaning cycle if needed. This ensures cleaning efficiency.

Check the compressed air system regularly. Ensure it runs normally. Also, verify the pressure is stable and meets requirements.

Monitor the dust emission concentration constantly. If you see dust escaping, check for damaged bags or poor seals immediately. Seal any air leaks. Repair or replace the bags.

For other supporting equipment, always follow the instructions. Use the supplier’s provided “Product Manual and Maintenance Guide” for selection, installation, commissioning, maintenance, and repair.