Waste Incineration Flue Gas Dust Removal Process: What Material of Filter Bag is Suitable?

Flue gas produced during waste incineration has several unique characteristics. Understanding these features is crucial for selecting the appropriate filter bag material.

- High Temperature and Pressure

Flue gas typically exits at 800°C to 1100°C. This high temperature and pressure pose challenges for dust removal equipment. - Complex Gas Composition

Incinerating waste releases various gases, including sulfur oxides, nitrogen oxides, hydrochloric acid (HCl), hydrofluoric acid (HF), and toxic organic pollutants like dioxins and furans. It also releases heavy metals such as mercury, cadmium, and lead. - High Calorific Value

The flue gas contains significant thermal energy. This energy can be recovered, improving overall efficiency. - Strong Acidity

The process generates many acidic gases, such as sulfur dioxide and hydrochloric acid. These gases can react with water, leading to environmental pollution. - High Flow Rate

Strong airflow in the incinerator results in a high flue gas flow rate, increasing pressure and wear on equipment. - Fine Particulate Size and High Viscosity

The fine particulate size and high viscosity of the dust complicate the dust removal process. - High Moisture Content and Dew Point Temperature

The moisture content in waste is high. During combustion, steam is produced, resulting in a moisture content of 23% to 30% and a dew point temperature of about 140°C. This requirement raises standards for dust removal equipment.

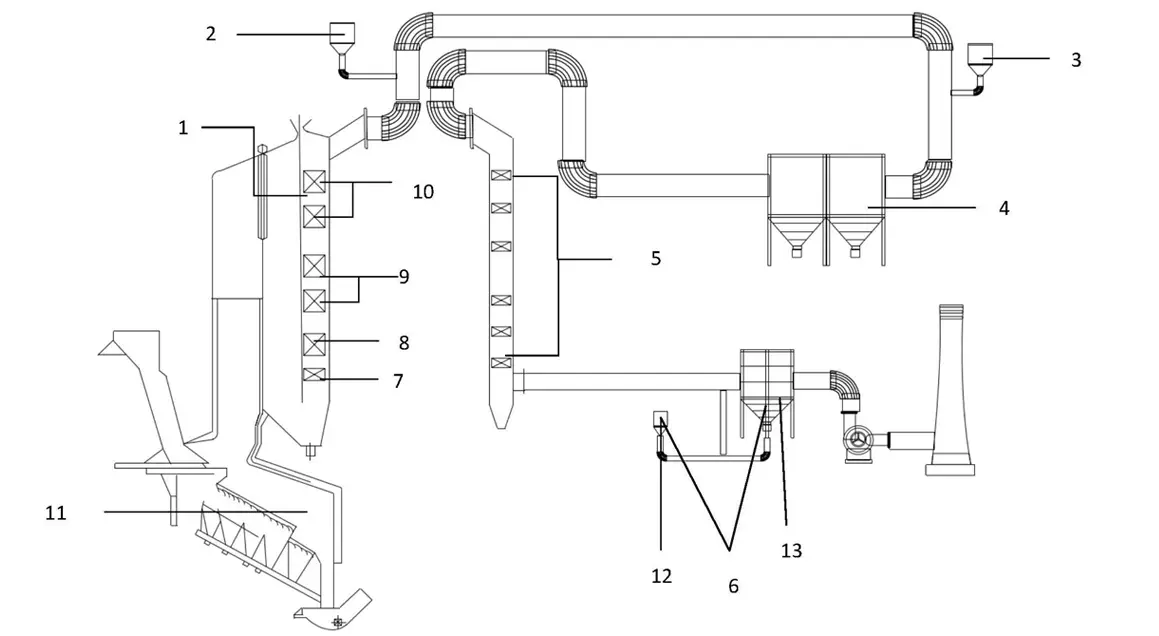

Overview of Waste Incineration Dust Removal Process

The dust removal process for waste incineration flue gas consists of several steps. These steps aim to purify the flue gas to meet environmental standards.

Pre-treatment

This stage includes cooling, desulfurization, and denitrification, which prepare for effective dust removal.Dry Dust Removal

Equipment like electrostatic precipitators and bag filters remove solid particulate matter from the flue gas.Semi-dry Dust Removal

Techniques such as cyclonic and wet electrostatic separation are used to eliminate gaseous particulate matter, further purifying the gas.Acid Removal

Alkaline sprays help remove acidic gases, reducing their environmental impact.Flue Gas Humidity Control

Adjusting humidity improves the efficiency of subsequent adsorption and denitrification processes.Post-treatment

Finally, washing, adsorption, and catalytic processes remove any remaining pollutants, achieving higher purification levels.

By integrating these processes, operators can effectively reduce pollutant emissions from waste incineration flue gas. This ensures compliance with national environmental standards and enhances resource recovery.

Guide to Choosing Filter Bag Materials for Waste Incineration

Selecting the right filter bag material is crucial in the waste incineration industry. The following materials are commonly recommended:

1.Polyester (PET)

3.Aramid (e.g., Nomex)

5.Modified Polyester

Conclusion

Choosing the right filter bag material is vital for the success of the waste incineration dust removal process. By considering specific process conditions, gas composition, and equipment types, operators can effectively select the appropriate filter bag material, size, and specifications. This ensures efficient dust removal and compliance with environmental standards, contributing to sustainable development.

For more information or professional advice, please contact us. We look forward to assisting you!