The Science, Applications, and Impact of Power Stability on Fabric Filter Performance

In the demanding world of industrial manufacturing and processing, air quality isn’t just a regulatory checkbox – it’s a critical factor for environmental compliance, worker safety, operational efficiency, and community relations. Among the most effective and widely deployed technologies for capturing particulate matter (PM) from industrial exhaust streams stands the Fabric Filter, commonly known as a Baghouse. As your partner in reliable industrial operations, we understand that robust processes require clean air and, importantly, stable power to ensure their continuous effectiveness. While our core expertise lies in delivering precision voltage stabilization solutions to keep your critical equipment running smoothly, understanding key pollution control technologies like fabric filters is vital for integrated plant performance. This article explores the fundamentals, advantages, applications, and critical operational needs of fabric filter systems.

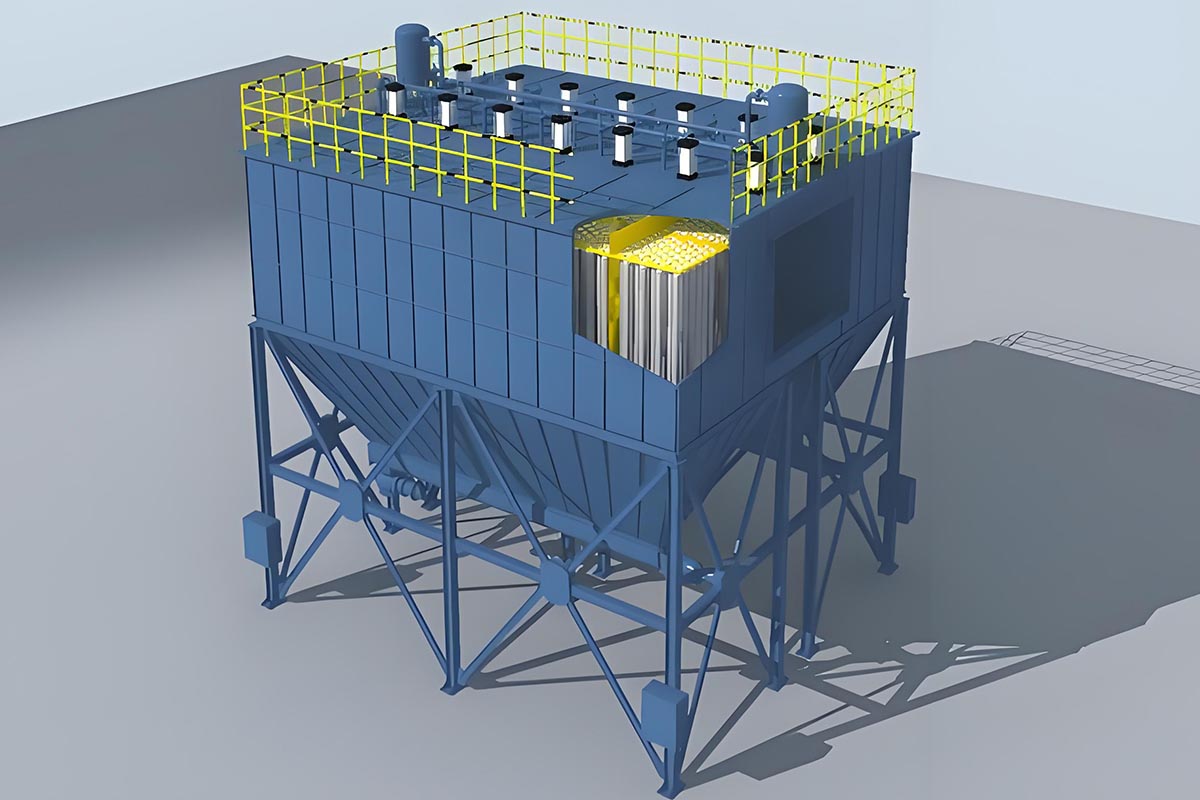

How Do Fabric Filters Work? The Science of Particle Capture

At its core, a fabric filter system relies on a simple yet powerful principle: physical filtration. Contaminated gas laden with dust or fumes is forced through a series of fabric filter bags (tubes or envelopes). The fabric acts as a physical barrier, trapping particles on its surface or within its porous structure while allowing the cleaned gas to pass through.

Screw conveyors come in several configurations tailored to specific applications:

The Process: Step by Step

- Dirty Gas Inlet: The contaminated gas stream enters the baghouse, often through an inlet plenum designed to distribute the flow evenly.

- Filtration: The gas flows through the fabric filter media. Several capture mechanisms are at play:

- Sieving: Particles larger than the pore openings in the fabric are physically blocked.

- Inertial Impaction: Larger, heavier particles cannot follow the gas streamlines around fibers and collide with them.

- Interception: Particles following the gas stream come within one particle radius of a fiber and are captured.

- Diffusion: Very fine particles (< 0.1 µm) exhibit Brownian motion, causing them to randomly collide with fibers.

- Electrostatic Forces: Some fabrics can carry a charge, attracting oppositely charged particles.

- Cake Formation: Initial collection forms a porous layer of dust on the fabric surface called the “dust cake.” This cake itself becomes an extremely efficient primary filtration layer.

- Clean Gas Outlet: The filtered gas exits the bags and moves to the clean air plenum before being discharged through the stack.

- Cleaning Cycle: As the dust cake builds, pressure drop across the filter increases. To maintain efficiency and airflow, the cake must be periodically removed (“cleaned”) without excessive dislodgement into the clean gas stream. Cleaning methods vary significantly (more below).

Key Components of a Fabric Filter System

- Filter Housing/Structure: Robust enclosure, typically steel, containing the filter bags and separating dirty and clean gas zones.

- Tube Sheet: A metal plate dividing the housing into dirty (inlet) and clean (outlet) sides, with holes through which the filter bags are mounted and sealed.

- Filter Bags/Cages:

- Filter Media: The fabric itself, chosen based on temperature, chemistry, particle size, and required efficiency (e.g., polyester, fiberglass, PTFE, Ryton, P84). Key forms are:

- Woven: Traditional fabrics like fiberglass.

- Non-Woven (Felted): The most common today, offering higher surface filtration efficiency. Needled felts provide depth filtration initially transitioning to surface filtration.

- Support Cages: Internal metal structures preventing bag collapse under suction or during cleaning.

- Filter Media: The fabric itself, chosen based on temperature, chemistry, particle size, and required efficiency (e.g., polyester, fiberglass, PTFE, Ryton, P84). Key forms are:

- Cleaning System: Essential mechanism for dislodging accumulated dust cake. Major types:

- Pulse-Jet (Reverse Air): High-pressure compressed air pulses injected down the bag clean side, flexing the bag and dislodging cake. Requires reliable, clean compressed air supply.

- Reverse Air: Gentle reversal of gas flow direction collapses the bags.

- Shaker: Mechanical shaking of the bags dislodges dust.

- Dust Collection/Hopper: Conical or pyramidal bottom section designed to collect dislodged dust for discharge (often via rotary valves or screw conveyors). Requires isolation valves and level sensors.

- Fans/Draft Systems: Induce flow through the system. Fan power demand is directly affected by filter pressure drop. Stable power ensures consistent fan speed and critical airflow.

- Control System: Modern baghouses use sophisticated PLCs/DCS to automate cleaning cycles based on differential pressure (ΔP), timers, or hybrid controls. Requires stable power to operate reliably and protect against control logic faults.

Advantages of Fabric Filter Systems

- Exceptionally High Efficiency: Capable of capturing >99.9% of PM, including fine and submicron particles (PM2.5/PM10). Often the only technology capable of meeting stringent emission limits for fine particulates.

- Broad Application Range: Handles various dust types (dry, abrasive, sticky) and fumes across numerous industries (see below).

- Consistent Performance: Maintain high efficiency even when inlet dust loading varies.

- No Pre-Cooling Often Needed: Unlike Wet Scrubbers or Electrostatic Precipitators (ESPs), they can often handle higher temperature gases (depending on filter media limits).

- No Wastewater Stream: Avoids the complexity and cost of water treatment associated with scrubbers.

- Recovery of Product: Valuable process dusts (e.g., cement, flour, catalysts) can be captured and reused.

- Relatively Low Operating Costs (Once Installed): Primarily involve compressed air (pulse-jet), fan power, and periodic bag replacement.

Common Industrial Applications for Fabric Filters

Fabric filters are ubiquitous in industries generating significant airborne particulates:

- Cement & Lime Kilns: Capturing raw mill, kiln, clinker cooler, and cement mill dust. Requires high-temperature media.

- Coal-Fired Power Plants & Biomass Boilers: Primary PM control on smaller units or as polishing filters after ESPs on larger units.

- Metals Production & Processing: Foundries (cupola, electric arc furnace dust), smelters, steel mills (sinter plants, BOF fumes), metal grinding/finishing.

- Woodworking: Sawdust and wood fiber collection from sanding, cutting, routing.

- Food & Agriculture: Flour and grain dust, sugar processing, feed mills.

- Chemical & Pharmaceutical: Handling catalyst fines, powders, intermediates. Requires specialized corrosion-resistant media.

- Waste Incineration: Controlling fly ash emissions. Requires high-temperature, corrosion-resistant media.

- Mining & Minerals Processing: Crushing, grinding, drying, conveying.

The Critical Role of Stable Power and Process Control

While fabric filters are robust, their reliability hinges on stable operation, particularly for critical components:

- Cleaning System: Pulse-Jet baghouses depend heavily on a clean, stable supply of compressed air at the correct pressure. Voltage fluctuations impacting air compressors can lead to insufficient cleaning, causing increased ΔP, reduced airflow, and potentially bag blinding.

- Control Systems: The PLC/DCS managing cleaning cycles, fan speed, valve sequencing, and alarms requires uninterrupted, stable power. Power surges, sags, or interruptions can cause system malfunctions, lost cleaning cycles, or failure to detect critical conditions (like high hopper level).

- Induced Draft (ID) Fans: These fans are the engine driving airflow through the process and filter. Voltage fluctuations can cause fan speed variations, leading to:

- Reduced Capture at Hoods: Insufficient flow pulls less dust from the source.

- Increased Filter Pressure Drop: Lower flow reduces cake dislodgement during cleaning cycles.

- Potential Process Upset: Imbalances in combustion air or process gas flow.

- Material Handling Systems: Rotary valves, screw conveyors, and pneumatic transfer systems removing collected dust from hoppers rely on steady power. Power issues can lead to hopper overfilling, causing severe bag damage and even shutdown.

Implementing industrial-grade voltage stabilizers protects these vital components from power anomalies. Our tailored solutions ensure consistent voltage to compressors, control panels, motors, and fan drives, safeguarding fabric filter performance and longevity, preventing costly downtime and emission violations.

Bag Selection: Choosing the Right Fabric

Selecting the optimal filter media is paramount:

- Gas Temperature: Defines the base requirement (e.g., Polyester ~135°C, PTFE ~260°C).

- Chemical Composition: Acidic/alkaline gases, moisture, and other chemicals dictate corrosion resistance needs (e.g., PTFE, Ryton, PPS for harsh environments).

- Particle Characteristics: Size, shape, abrasiveness, hygroscopicity (tendency to absorb moisture), and stickiness influence fabric structure, surface treatments, and cleaning method. Fine powders often need dense non-wovens; hygroscopic materials need moisture resistance.

- Required Efficiency: Influences fabric weight, structure, and whether surface coatings (e.g., membrane laminates) are needed for ultra-high efficiency.

- Cleaning Method: Pulse-jet cleaning requires a stiff felt capable of rapid flexing and release; shaker systems use different constructions. Consult fabric suppliers for guidance.

Fabric Filter Maintenance: Ensuring Longevity and Performance

- Regular Inspections: Visual checks for bag leaks, damaged cages, casing integrity, airflow, and cleaning mechanisms.

- Preventive Bag Replacement: Don’t wait for catastrophic failure; plan replacements based on history and condition.

- Monitoring Differential Pressure (ΔP): Key indicator of filter condition. Rising ΔP signals cleaning issues or blinding.

- Dust Discharge: Ensure hoppers are emptying reliably to prevent bag contact damage or pluggage.

- Compressed Air System: Maintain dry, clean air at the correct pressure for pulse-jet systems. Voltage stabilizers protect compressors.

- Keep Records: Track bag life, cleaning cycles, ΔP trends, and maintenance actions.

Fabric Filters vs. Electrostatic Precipitators (ESPs) vs. Wet Scrubbers

- Fabric Filters: Excel at very high efficiency on fine particulate, handle varying loads well, moderate capital cost, moderate to higher operating cost (bag replacement), handle high temps (with right media), no water/waste.

- ESPs: Best for very large gas volumes with moderate PM loads, can handle very high temps, lower pressure drop = potentially lower fan power, higher capital cost, sensitive to dust resistivity/chemistry/load fluctuations, less efficient on fine PM than fabric filters.

- Wet Scrubbers: Effective for gases and some particulates (especially sticky/moist), handle high temp gases (with quench), lower capital cost, high operating cost (water/power/treatment), produce wastewater/sludge.

Fabric Filter FAQs

- Bag lifespan varies enormously (1-5+ years), depending on the application, operating conditions (temperature, gas chemistry, abrasiveness), cleaning intensity, bag material quality, and maintenance. Harsh environments (e.g., waste incineration, high-abrasion) generally have shorter bag lives.

- Yes, but only with the appropriate filter media selection. Standard polyester bags are limited to around 135°C (275°F). Fiberglass can handle ~230°C (450°F). Specialty materials like PTFE, Ryton (PPS), P84, and Nomex are designed for continuous operation at significantly higher temperatures (e.g., PTFE ~260°C / 500°F). Always consult with media suppliers.

- Key warning signs include:

- A noticeable, sustained increase in differential pressure (ΔP) across the filter.

- Visible opacity or dust in the stack exhaust.

- Unusual noises from the cleaning system or fan.

- Hopper pluggage or discharge problems.

- Erratic control system behavior.

- High compressed air consumption (for pulse-jet).

- Power instability directly threatens key components:

- Cleaning System Failure: Voltage sags can disable compressors, leading to insufficient cleaning and bag blinding.

- Control System Malfunctions: PLCs and sensors are vulnerable to surges/sags, causing incorrect cleaning cycles or failure to respond to alarms.

- Fan Speed Fluctuations: This disrupts critical process airflow, reducing capture efficiency at dust sources and negatively impacting filter cleaning and overall process balance.

- Material Handling Jams: Power interruptions stop dust discharge systems, risking hopper overfill and severe bag damage. Investing in voltage stabilizers protects against these risks, ensuring continuous compliance and operational reliability.

Fabric filters remain the gold standard technology for achieving the highest levels of particulate matter capture across a vast array of industrial processes. Their efficiency, versatility, and reliability make them indispensable for meeting stringent environmental regulations and protecting worker health. Understanding the principles of operation, critical components, maintenance requirements, and the nuances of bag selection is crucial for maximizing performance and lifespan.

Equally critical is recognizing that fabric filters are not standalone islands within an industrial facility. Their effectiveness relies on the seamless operation of interconnected systems, particularly the stable and reliable supply of electrical power. Fluctuations in voltage can cripple cleaning mechanisms, destabilize control systems, disrupt vital airflow, and halt dust removal, leading to reduced efficiency, potential equipment damage, costly downtime, and emission exceedances.

As experts in safeguarding industrial processes through precision voltage stabilization, we emphasize that protecting your critical air pollution control investment requires protecting its power source. Ensuring clean power to compressors, controls, motors, and fans isn’t just an operational detail; it’s a fundamental requirement for continuous compliance, environmental responsibility, and optimal plant performance. When your fabric filter runs smoothly with stable power, you breathe easier in more ways than one.