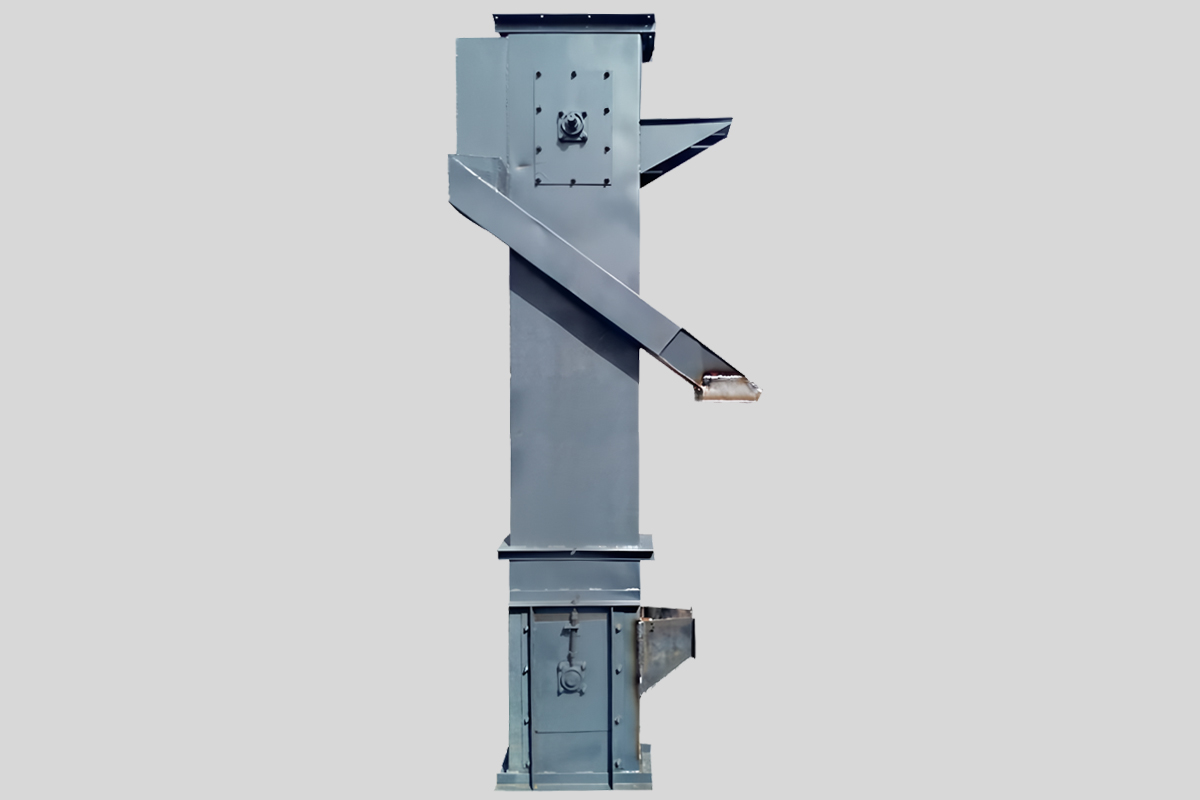

Stop Bucket Elevator Dust Leaks for Good: A Root-Cause Solution

In many industrial settings, bucket elevators frequently develop dust leakage and emissions after prolonged operation. This not only compromises the workshop environment but can also shorten equipment life and increase maintenance costs. So, how can this be effectively resolved? By focusing on two key areas, you can control dust leakage at its source.

1. Seal Wear: The Primary Source of Dust Leakage

Critical sealing points in bucket elevators, such as slide plates and shaft ends, are subject to constant friction, vibration, and high temperatures. Over time, these seals degrade and crack. Once seals fail, fine dust escapes through the gaps, leading to persistent leakage.

The solution lies in proactive inspection and timely replacement.

Implement a regular seal inspection schedule based on operational intensity. Replace any worn or hardened seals immediately. Opt for high-quality sealing materials—such as wear-resistant, high-temperature tolerant engineering rubber or polyurethane—to significantly enhance seal durability and minimize dust leakage from seal failure.

2. Material Impact & Airflow Disruption: Key Factors Driving Dust Emissions

When material falls from height with significant speed and drop, it impacts the elevator casing—either at the bottom or intermediate sections. This disrupts internal airflow, stirring up dust. Without effective internal dust suppression, these fine particles escape through gaps in inspection doors and joint connections.

The remedy: install induced draft and dust removal systems.

By creating suction points at appropriate locations and connecting them to external dust collection equipment, a slight negative pressure is maintained inside the elevator. This effectively draws out airborne dust before it can escape.

3. Don’t Overlook Daily Preventive Maintenance

Beyond these targeted measures, consistent preventive maintenance is essential. Regularly clean accumulated dust inside the elevator, inspect the condition of bearings and chains, and monitor for unusual vibration or noise during operation. These steps help detect potential issues early, preventing minor problems from turning into major failures.